Custom repairs target specific sections of damaged pipe, saving time and money

National Underground Group’s rehabilitation support services maximize repair efficiency of subsurface infrastructure by eliminating the need to replace or reline entire pipelines or excavate the surface area under which they run. Beyond providing the latest infrastructure rehabilitation methods and technologies, our experienced professionals have the expertise to provide complete, customer-based solutions in-house and effectively and efficiently manage rehabilitation operations, helping to ensure projects meet design and budget requirements.

Proven methods and technologies deliver customer-driven solutions

Chemical Grouting is composed of low-viscosity polymers and silicates used in structural and water control applications. The grouting can be injected through leaking joints, faults, cracks, annulus at lateral openings in lined pipe and other areas. For rehabilitation in these areas, chemical grouting is the only technique that permeates the external soil and voids around the leak, stopping ground water flow into the collection system and keeping sewage flows within the system

Chemical grouting can be used to stop infiltration in several subsurface infrastructure rehabilitation applications:

- Sewer-pipe joints

- Sewer-pipe circumferential cracks

- Lateral to main connections

- Lateral-pipe joints

- Manhole rings and base joints

- Manhole brick structures

- Exposed-annulus flow between host pipes and liner at lateral cutouts

- Exposed annulus flow between host pipe at liner entry into manholes

Cured-in-place-pipe (CIPP) Segmental Patches provide a trenchless, point repair solution for 3- to 24-inch diameter pipes. It can be used in conjunction with CIPP Installations or as a stand-alone application over offset joints, pipe separations and pipe cracks. It can also be used to seal off interior drops and cap off unwanted laterals.

Each point repair system is custom-assembled for the project requirements and includes all the equipment and materials to help ensure effective and efficient installations. The materials include a specially designed glass-reinforced fabric and 2-part ambient-cure silicate resin. Once cured, it exceeds the structural requirements of ASTM F1216 for all sewer and storm water pipes having a circular or oval cross section and it has a 50-year service life. The point-repair resin is odor-free, styrene-free and VOC-free. It is not hazardous to humans or the environment and comes in a container that ensures no leaks and a long shelf life.

Rausch Quick-Lock Mechanical Repair is a mechanical point repair system that is implemented on the pipe’s inner wall. This system consists of a 316L stainless steel sleeve structural body, covered by a seamless EPDM compression seal. The sleeve is inserted through the manhole into the pipe and placed over the damaged section. Using an inflatable packer, the sleeve is then expanded and permanently locked into position.

The system’s sleeve can be installed with flow present because the packer is hollow, allowing uninterrupted flow capacity. The mechanical point repair method provides several advantages:

- Trenchless no-dig spot repair

- Permanent, reliable and instant fix

- Passes air and water pressure testing

- Reinstates structural strength and integrity of deformed and damaged pipe

- Can be installed with flow present

- Easy and quick installation – no cure time

- Applicable for internal pressure up to 220 psi

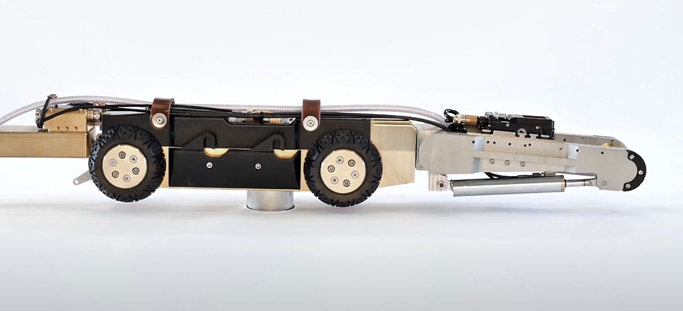

Schwalm Robotics provide fast and efficient grinding and cutting solutions to remove pipe obstructions such as attached concrete, protruding ferrous or PVC laterals, offset joints or very large tap roots. When necessary, they can be fitted with a milling head to cut through clay, cement and even ductile iron. Unlike conventional methods, this equipment enables us to isolate the repair while minimizing destruction to the rest of the host pipe. Schwalm air-driven robots are capable of operating in 6- to 24-inch diameter pipes.

The Picote Smart Cutter™ navigates 90° bends and diameter transitions to accurately open and shape lateral CIPP connections without damaging host pipes composed of cast iron, clay, concrete and plastic pipes. It removes scale, obstructions and resin slugs and can be used as a preparatory measure for brush coating the pipe’s inner wall.

Water management solutions for infrastructure rehabilitation

National Underground Group’s rehabilitation support team understands water management is a key consideration for any successful trenchless rehabilitation project. It is crucial that areas slated for repair are properly isolated from water both within and outside the system as well as from infiltration and inflow. If the efforts made to remove and isolate water from a system are not managed correctly, this can lead to failures, overflows, costly delays, and even project cancellations.

Our experienced team handles a variety of different types of water situations such as:

- Submerged pipe systems that need to be plugged and pumped down or require more extensive isolation through the installation of cofferdams or Portadams

- High groundwater tables that require a well point system

- High flow in host pipes themselves, where bypass operations are used to take flow off the pipe and pump it around

Service Lines

Tri-State Utilities

Tri-State Utilities provides turnkey pipeline rehabilitation solutions and utilizes industry-leading trenchless pipe lining technologies, including the cured-in-place-pipe (CIPP) lining method, on sanitary sewers and storm drains. Customers trust Tri-State Utilities for its in-depth expertise, local knowledge, faster response time, quality assurance and cost-efficiency.

Go to Tri-State Utilities Go to Tri-State Utilities Go to Tri-State Utilities

Tri-State Utilities

Tri-State Utilities provides turnkey pipeline rehabilitation solutions and utilizes industry-leading trenchless pipe lining technologies, including the cured-in-place-pipe (CIPP) lining method, on sanitary sewers and storm drains. Customers trust Tri-State Utilities for its in-depth expertise, local knowledge, faster response time, quality assurance and cost-efficiency.

Go to Tri-State Utilities Go to Tri-State Utilities Go to Tri-State Utilities