Application-specific technologies that clean and assess pipe infrastructure

Prior to performing inspection and rehabilitation operations on wastewater pipe, it must be free of debris, blockages and inner wall deposits. And, without a thorough and accurate assessment that provides quality data of a pipe’s condition, undertaking a major pipe infrastructure project can be inefficient and hazardous.

Accordingly, National Underground Group provides pipe infrastructure stakeholders services that thoroughly clean pipelines to fully restore flow capacity or as a prelude to rehabilitation operations. And, our advanced pipe assessment technologies provide a thorough inspection of pipe conditions as an aid to planning current and future infrastructure projects. Through collection of precise data, which is offered via cloud-based technology, our clients get the clearest picture of pipe condition. This provides an essential roadmap for identifying and prioritizing infrastructure rehabilitation requirements and as an aid to developing operational budgets.

Related Services

CCTV Pipeline and Manhole Inspection & Sewer Lateral Inspection

CCTV pipeline and manhole inspection & sewer lateral inspection technologies provide thorough and accurate condition assessments of major pipe infrastructure. Inspecting sewer service laterals is paramount when directional drilling is scheduled for the infrastructure installation in areas where past drilling for gas or telecommunication lines may have intersected laterals. Not locating and assessing sewer laterals in advance creates the risk of utility lines being installed through existing wastewater infrastructure.

See CCTV Pipeline and Manhole Inspection & Sewer Lateral Inspection See CCTV Pipeline and Manhole Inspection & Sewer Lateral Inspection See CCTV Pipeline and Manhole Inspection & Sewer Lateral Inspection

Pipe and High-Performance Sewer Cleaning

Pipe and high-performance sewer cleaning is done by experienced cleaning crews who assess the cleaning job and determine the best process and equipment for the job. We offer advanced pipe cleaning solutions for pipes of any diameter, using hydro jet equipment or mechanical methods to meet the specific requirements of our clients. After scouring and sanitizing storm or sewer pipes, we apply a powerful vacuum to remove debris.

See Pipe and High-Performance Sewer Cleaning See Pipe and High-Performance Sewer Cleaning See Pipe and High-Performance Sewer Cleaning

Sewer Mainline and Lateral Locates

Sewer mainline and lateral locates provide advance locating and inspection technologies to eliminate damage to subsurface infrastructure during excavation. During the process, every inch of an infrastructure network, from the mainline through the length of a lateral, is inspected for dangerous gas utility line cross bores, pipe degradation and structural issues. This service utilizes cloud technologies to link inspection data (including videos and GPS observations) to geographic information system (GIS)-based mapping systems.

See Sewer Mainline and Lateral Locates See Sewer Mainline and Lateral Locates See Sewer Mainline and Lateral Locates

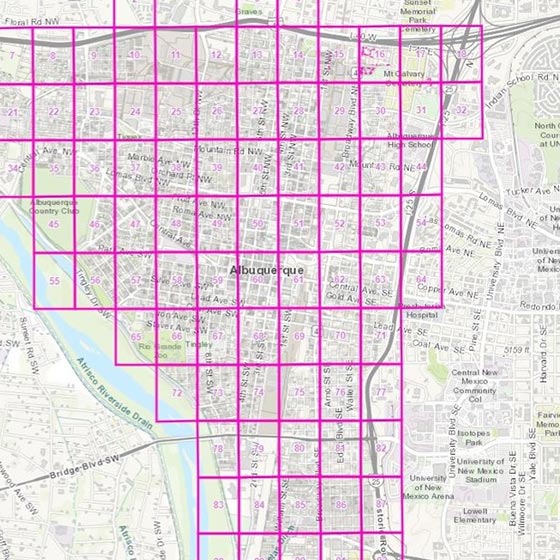

GIS Pipeline Mapping Services

GIS pipeline mapping services provide a quality data management process that includes the ability to track production, isolate inconclusive inspections for further review, and date-stamp final cleared locations. This enables full viewer access to the GIS mapping software by log-in and eliminates time spent sorting, reviewing and prioritizing essential sewer and natural gas line GIS data. The ability to easily locate accurate underground facilities enables utilities, engineers and municipalities to coordinate their infrastructure maintenance operations.

See GIS Pipeline Mapping Services See GIS Pipeline Mapping Services See GIS Pipeline Mapping Services

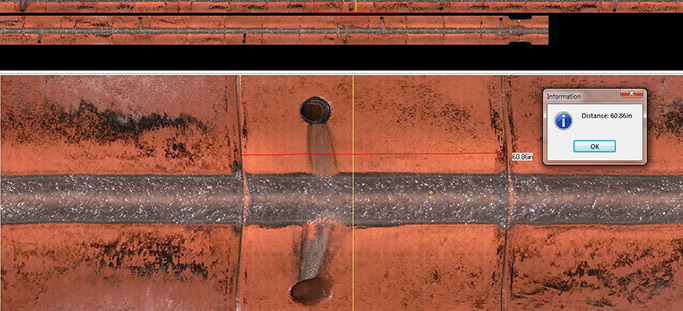

Multi-Sensor Inspection (MSI)

National Underground Group’s multi-sensor inspection technologies provide certified National Association of Sewer Service Companies (NASSCO) inspection data. This data can be used to develop risk analysis parameters that include comparing a pipe’s condition and its likelihood of failure with the consequences of that failure. This enables municipalities, utility providers, pipe inspection contractors and engineering firms to develop accurate budgets and conduct effective and efficient preventive maintenance and rehabilitation programs for pipe infrastructure.

See Multi-Sensor Inspection (MSI) See Multi-Sensor Inspection (MSI) See Multi-Sensor Inspection (MSI)

CCTV Pipeline and Manhole Inspection & Sewer Lateral Inspection

CCTV pipeline and manhole inspection & sewer lateral inspection technologies provide thorough and accurate condition assessments of major pipe infrastructure. Inspecting sewer service laterals is paramount when directional drilling is scheduled for the infrastructure installation in areas where past drilling for gas or telecommunication lines may have intersected laterals. Not locating and assessing sewer laterals in advance creates the risk of utility lines being installed through existing wastewater infrastructure.

See CCTV Pipeline and Manhole Inspection & Sewer Lateral Inspection See CCTV Pipeline and Manhole Inspection & Sewer Lateral Inspection See CCTV Pipeline and Manhole Inspection & Sewer Lateral Inspection

Pipe and High-Performance Sewer Cleaning

Pipe and high-performance sewer cleaning is done by experienced cleaning crews who assess the cleaning job and determine the best process and equipment for the job. We offer advanced pipe cleaning solutions for pipes of any diameter, using hydro jet equipment or mechanical methods to meet the specific requirements of our clients. After scouring and sanitizing storm or sewer pipes, we apply a powerful vacuum to remove debris.

See Pipe and High-Performance Sewer Cleaning See Pipe and High-Performance Sewer Cleaning See Pipe and High-Performance Sewer Cleaning

Sewer Mainline and Lateral Locates

Sewer mainline and lateral locates provide advance locating and inspection technologies to eliminate damage to subsurface infrastructure during excavation. During the process, every inch of an infrastructure network, from the mainline through the length of a lateral, is inspected for dangerous gas utility line cross bores, pipe degradation and structural issues. This service utilizes cloud technologies to link inspection data (including videos and GPS observations) to geographic information system (GIS)-based mapping systems.

See Sewer Mainline and Lateral Locates See Sewer Mainline and Lateral Locates See Sewer Mainline and Lateral Locates

GIS Pipeline Mapping Services

GIS pipeline mapping services provide a quality data management process that includes the ability to track production, isolate inconclusive inspections for further review, and date-stamp final cleared locations. This enables full viewer access to the GIS mapping software by log-in and eliminates time spent sorting, reviewing and prioritizing essential sewer and natural gas line GIS data. The ability to easily locate accurate underground facilities enables utilities, engineers and municipalities to coordinate their infrastructure maintenance operations.

See GIS Pipeline Mapping Services See GIS Pipeline Mapping Services See GIS Pipeline Mapping Services

Multi-Sensor Inspection (MSI)

National Underground Group’s multi-sensor inspection technologies provide certified National Association of Sewer Service Companies (NASSCO) inspection data. This data can be used to develop risk analysis parameters that include comparing a pipe’s condition and its likelihood of failure with the consequences of that failure. This enables municipalities, utility providers, pipe inspection contractors and engineering firms to develop accurate budgets and conduct effective and efficient preventive maintenance and rehabilitation programs for pipe infrastructure.

See Multi-Sensor Inspection (MSI) See Multi-Sensor Inspection (MSI) See Multi-Sensor Inspection (MSI)