Utility locating expertise and inspection technologies guard infrastructure project safety and reduce cross bore-related risks

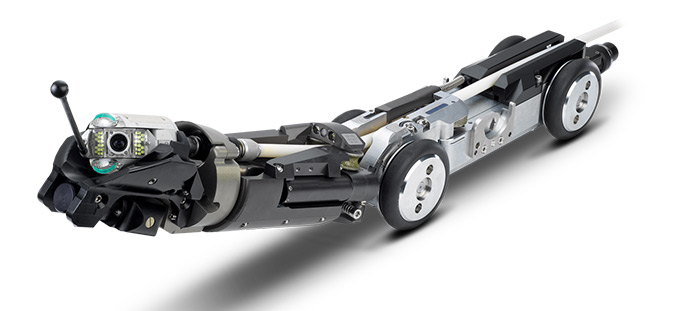

The cross-bore service professionals at National Underground Group conduct comprehensive inspection, location and data record management services for utility owners. A thorough underground pipe inspection conducted using advanced technology provides utility owners with backup data that confirms no threat was uncovered in the inspected area before new or replacement utility lines are horizontally drilled in proximity to existing wastewater infrastructure. These technologies maximize pipe inspection and location accuracy, increasing operational safety and efficiency, while reducing the exposure crews and property owners must endure during more intrusive programs.

Trenchless replacement projects often present risk, because conflicts can exist between both mains and service connections for crossing lines. Earning the name “legacy projects” from industry insiders, new project managers must often deal with older cross bore prevention efforts and poor record-keeping techniques when the utility lines installed used horizontal directional drilling methods that date back several decades.

By applying our comprehensive cross bore inspection and utility asset locating expertise in horizontal directional drilling applications, utility crews of all types can avoid drilling into existing sewer lines. We also conduct risk assessments and recommend where inspections should be performed in areas subjected to underground drilling. In addition to working with utility owners on new projects, our experts perform legacy inspections.

When necessary, our daylighting service can be used to uncover subsurface utilities and infrastructure safely and efficiently. This technique eliminates mechanical digging, which often puts work crews at risk and can damage subsurface infrastructure. This is especially important when trying to locate lines that carry hazardous materials or essential utilities. Using hydro excavation methods, this service can also remove debris and pressure-clean a variety of structures with minimal impact to the surrounding area. Our daylighting fleet of vac trucks operates across the nation with a range of service options capable of handling projects of all sizes.

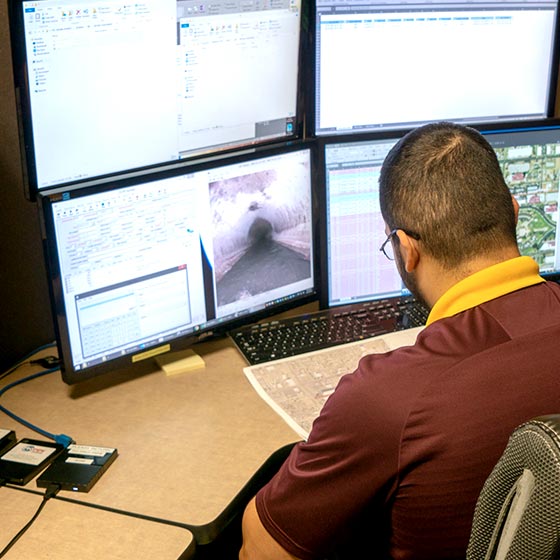

Our geographic information system (GIS) data integration implements a quality data management process by building a GIS-based time-stamped library of events as cross bore projects progress. This process provides our clients with easy, lifetime access to their inspection data that is maintained by cloud data management software and is accessible at any time, from any place. Our inspection technologies and data management help keep communities safe and reduce infrastructure project-related risk for utility owners and cities.

Related Services

Pre-Construction Mark and Locate

Pre-construction mark and locate services accurately identify existing subsurface utilities to help contractors guard against damaging them when they are in proximity to a planned excavation area. Services include locating existing lines and laterals using advanced robotic lateral launch systems that can quickly identify the main, each connection and the service lateral’s position up to the foundation of a structure.

See Pre-Construction Mark and Locate See Pre-Construction Mark and Locate See Pre-Construction Mark and Locate

Post-Construction Inspection

A comprehensive post-construction inspection is the surest way to verify sewer infrastructure has not been damaged during horizontal directional drilling. Inspections also provide project stakeholders confirmation that the integrity of existing wastewater infrastructure is intact and that the utility service area and its inhabitants are safe from harm caused by subsurface breaches or open utility lines.

See Post-Construction Inspection See Post-Construction Inspection See Post-Construction Inspection

Legacy Inspection

Legacy inspections provide comprehensive inspection and utility asset locating services to identify cross bores among existing sewer infrastructure buried in areas marked for excavation by directional drilling contractors. We also conduct risk assessments of regions and make recommendations for the best place to make inspections in locations where horizontal directional drilling has recently been done.

See Legacy Inspection See Legacy Inspection See Legacy Inspection

Daylighting

Daylighting uncovers subsurface utilities and infrastructure safely and efficiently. Hydrovac systems, dry vacuum excavation systems and combination trucks with equipment that control high-pressure water or pressurized air break up and cut the soil, while a high-flow vacuum system lifts the soil up and out of the excavation area. This eliminates mechanical digging, which often puts work crews at risk and can damage subsurface infrastructure.

See Daylighting See Daylighting See Daylighting

GIS Data Integration

Geographic Information System (GIS) data integration provides a quality data management process by building a GIS-based time-stamped library of events as cross bore projects progress. This data management process includes the ability to track production, isolate inconclusive cross bore inspections for further review, and date-stamp final cleared locations. GIS data integration utilizes cloud technologies to link inspection data (including videos and GPS observations) to GIS-based mapping systems.

See GIS Data Integration See GIS Data Integration See GIS Data Integration

Pre-Construction Mark and Locate

Pre-construction mark and locate services accurately identify existing subsurface utilities to help contractors guard against damaging them when they are in proximity to a planned excavation area. Services include locating existing lines and laterals using advanced robotic lateral launch systems that can quickly identify the main, each connection and the service lateral’s position up to the foundation of a structure.

See Pre-Construction Mark and Locate See Pre-Construction Mark and Locate See Pre-Construction Mark and Locate

Post-Construction Inspection

A comprehensive post-construction inspection is the surest way to verify sewer infrastructure has not been damaged during horizontal directional drilling. Inspections also provide project stakeholders confirmation that the integrity of existing wastewater infrastructure is intact and that the utility service area and its inhabitants are safe from harm caused by subsurface breaches or open utility lines.

See Post-Construction Inspection See Post-Construction Inspection See Post-Construction Inspection

Legacy Inspection

Legacy inspections provide comprehensive inspection and utility asset locating services to identify cross bores among existing sewer infrastructure buried in areas marked for excavation by directional drilling contractors. We also conduct risk assessments of regions and make recommendations for the best place to make inspections in locations where horizontal directional drilling has recently been done.

See Legacy Inspection See Legacy Inspection See Legacy Inspection

Daylighting

Daylighting uncovers subsurface utilities and infrastructure safely and efficiently. Hydrovac systems, dry vacuum excavation systems and combination trucks with equipment that control high-pressure water or pressurized air break up and cut the soil, while a high-flow vacuum system lifts the soil up and out of the excavation area. This eliminates mechanical digging, which often puts work crews at risk and can damage subsurface infrastructure.

See Daylighting See Daylighting See Daylighting

GIS Data Integration

Geographic Information System (GIS) data integration provides a quality data management process by building a GIS-based time-stamped library of events as cross bore projects progress. This data management process includes the ability to track production, isolate inconclusive cross bore inspections for further review, and date-stamp final cleared locations. GIS data integration utilizes cloud technologies to link inspection data (including videos and GPS observations) to GIS-based mapping systems.

See GIS Data Integration See GIS Data Integration See GIS Data Integration